5-1 QBY air diaphragm pump

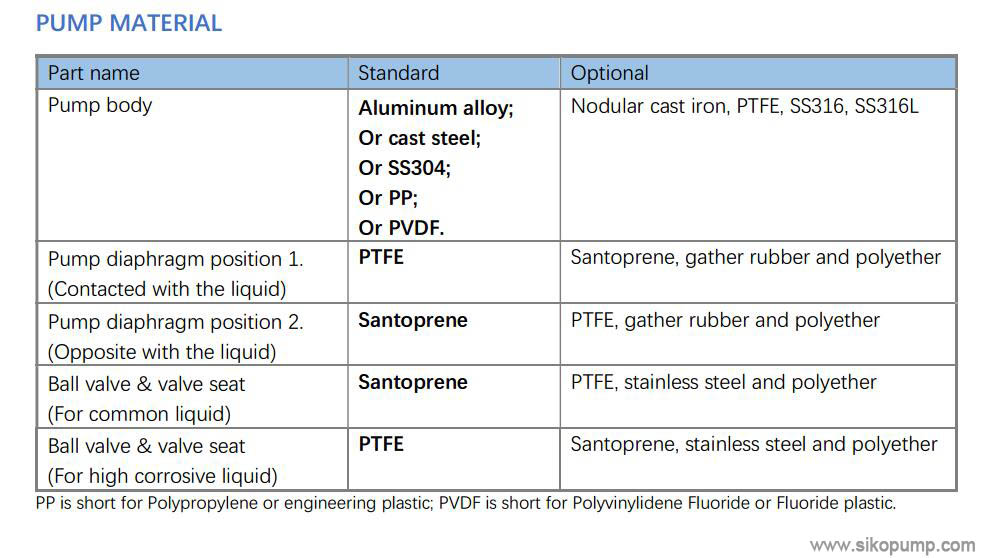

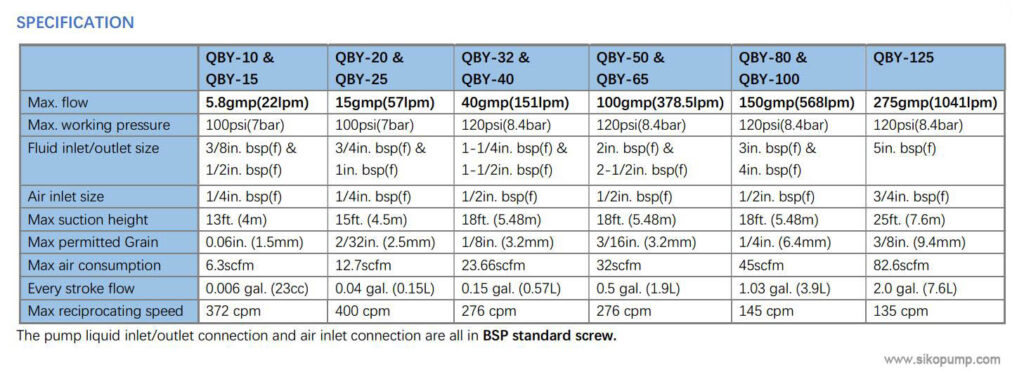

Air Operated Double Diaphragm Pump (AODD Pump), max flow to 275gmp(1041lpm), max pressure to 120psi(8.4bar), pump body material, Aluminum alloy, cast steel, SS304, PP, PVDF. Pump diaphragm material, PTFE and Santoprene.

QBY air diaphragm pump

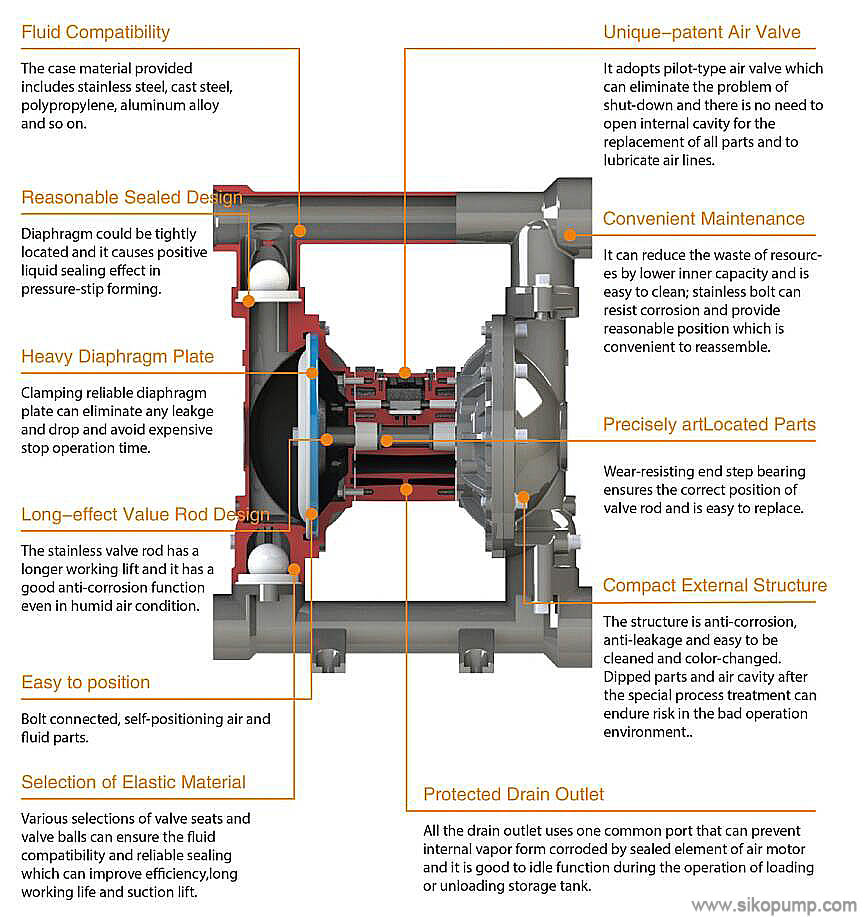

The QBY series pump is a diaphragm pump. It is also known as a Membrane pump, Air Operated Double Diaphragm Pump or Pneumatic Diaphragm Pump or AODD pump. This is a positive displacement pump. The pump uses a combination of the reciprocating action of a rubber, thermoplastic or Teflon diaphragm and suitable valves either side of the diaphragm to pump a fluid.

The QBY diaphragm pumps are driven with compressed air without the need of electric power. Widely used for leak proof applications in industries like petrochemical chemical metallurgy and ceramics etc. Applicable to liquids of leaky corrosive inflammable and explosive & hazardous properties.

SIKOPUMP is a leading QBY air diaphragm pump supplier and manufacturer from China.

Features.

- Liquid is completely isolated by the diaphragm, so pump have 100% proof of leakage.

- It is very good for the viscous, poisonous, corrosive liquid handing, No need to fill in priming water for QBY air operated diaphragm pump.

- Spacious flow and sound throughput performance, maximum permissible particle, little abrasion to the pump when handing slurry and impurity.

- Head lift and flow rate under steeples regulation through the opening regulation of valve.

Pump flow and pressure can be adjusted by the supply air, from 0.1 to 0.8Mpa. - This air diaphragm pump has no rotating elements and shaft seal.

Diaphragm makes the media handled completely separated from moving elements and working media. - It can work without electricity, suitable for inflammable and explosive

- The QBY air diaphragm pump can work when being submerged into media. Pump can work with idle operation.

- Easy operation and dependable service. Simple structure and less wearing parts.

- The air operated diaphragm pump is capable of handling viscous liquid.

- Environment temperature: 5 to 65 C degree

- Liquid temperature: -20C to 150 C degree, Liquid viscosity: to 10000cps

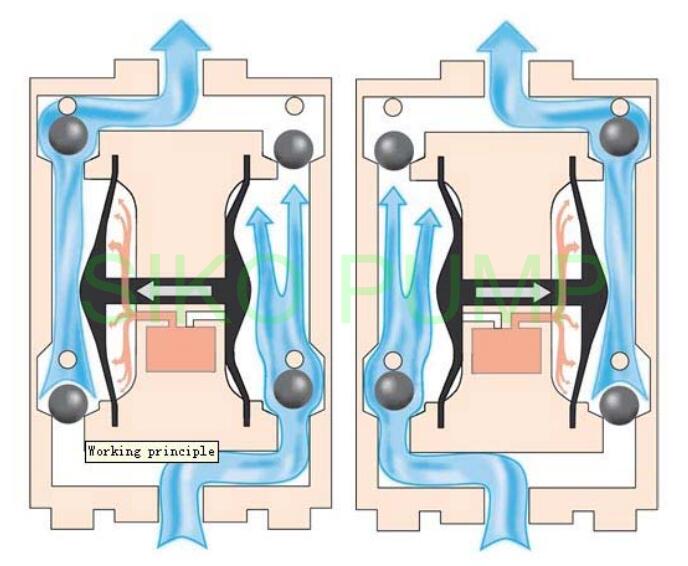

Working Principle

The QBY air operated diaphragm pumps are driven with compressed air without the need of electric power. Widely used for leak proof applications in industries like petrochemical chemical metallurgy and ceramics etc. Applicable to liquids of leaky corrosive inflammable and explosive & hazardous properties.

When the volume of a chamber of either type of pump is increased (the diaphragm moving up), the pressure decreases, and fluid is drawn into the chamber. When the chamber pressure later increases from decreased volume (the diaphragm moving down), the fluid previously drawn in is forced out. Finally, the diaphragm moving up once again draws fluid into the chamber, completing the cycle. This action is similar to that of the cylinder in an internal combustion engine.

If you are interested in QBY air diaphragm pump, just contact us SIKOPUMP freely.

The separate QBY pump catalog and detailed specification can be provided.

There are two sets of diaphragms for each pump, and two layers for each set of diaphragms.

So totally there are four pcs of diaphragms for each pump.

The inside layer of diaphragm is in Santoprene, and the outside layer of diaphragm is in PTFE, which is contacted with the liquid.

When for the high corrosive liquid, the ball valve and valve seat material is in PTFE, otherwise they are in Santoprene

Contact SIKOPUMP freely for each AODD pump model separate catalog. (detailed specification)

Scope of application for QBY air diaphragm pump

- Marine time: sewage, sea water, diesel oil drainage and transportation;

- Electricity: waste water, strong acid and strong alkaline drainage and transportation;

- Automobile: sealant, adhesive, plating liquor, solvent, paint supply and transportation;

- Chemical industry production: cleaning agent, binder, printing ink, cleaning/polishing, paint/dye;

- Mine: sewage, turbid water and thin slurry drainage

- Medicine: FDA material supply and transportation.