5-2 MP-R magnetic drive pump

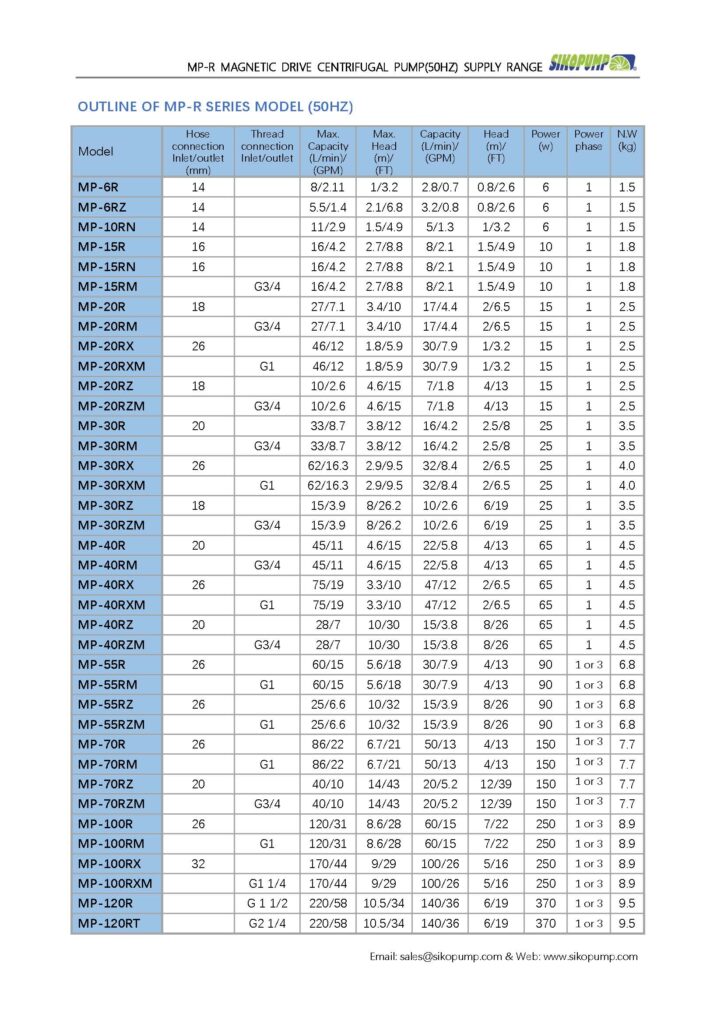

small power Mag-drive centrifugal pump, max flow to 380L/min, max head 22m, pump body material Carbon Fiber Reinforced Polypropylene, power to 2.2kw, single/three phase, 50Hz/60Hz, Similar to IWAKI pump. CE certificated.

MP-R magnetic drive pump

MP-R pump is a kind of magnetic drive centrifugal pump, also called mag-drive centrifugal pump.

SIKOPUMP is a leading magnetic drive pump supplier and manufacturer from China.

The MP-R magnetic drive pump is CE certificated.

Product Overview

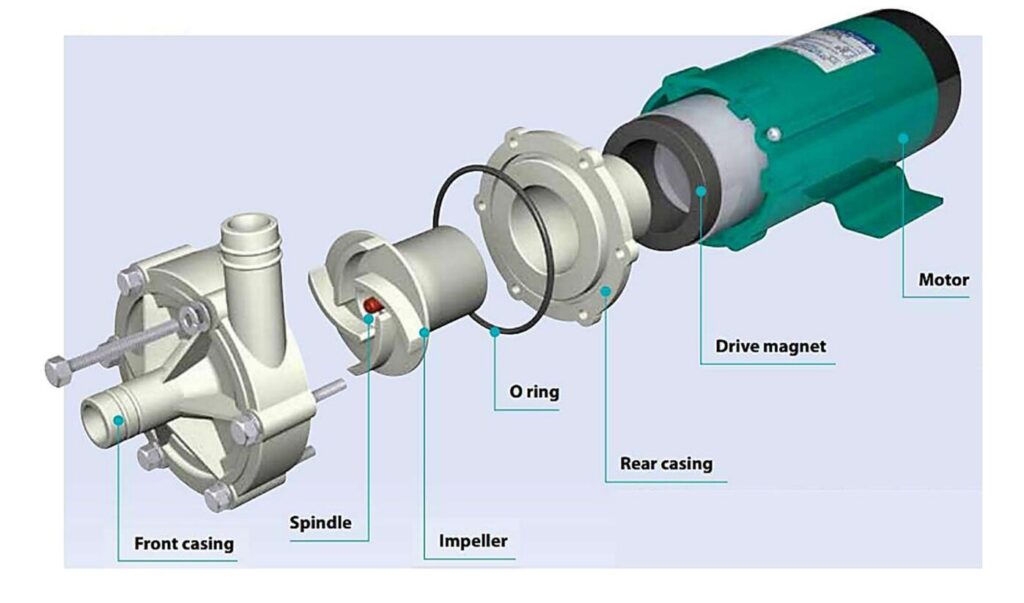

MP-R Magnetic driving centrifugal pump operation is similar to a standard centrifugal pump except the motor shaft seal is eliminated.

Instead, magnetic drive pumps are designed to isolate the wet end of the hydraulic circuit from the motor by driving an impeller and magnet assembly with a radial or axial drive magnet assembly attached to the motor shaft.

Motor torque is transmitted by the drive magnet through a plastic housing that separates the driven impeller magnet from the fluid being pumped. Leaks caused by shaft seal failure are eliminated. The end result is a more efficient seal-less centrifugal pump that will not leak and is capable of achieving up to 50 thousand hours of continuous duty operation.

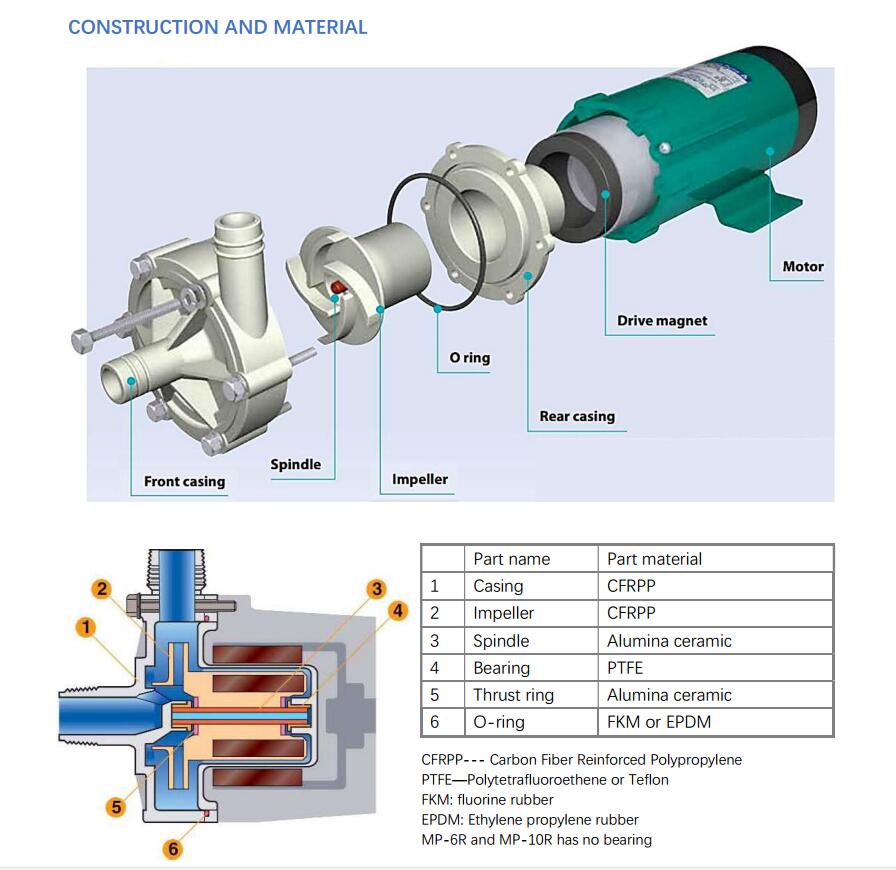

The impeller shaft and bearing system features an excellent combination of inert materials of construction to handle the most aggressive of chemicals and cooling passages designed to use the pumped liquid as a lubricating coolant.

SIKO uses ceramic shafts with either Teflon or ceramic thrust bearings as standard materials for each magnetic driving pump line. These robust features add tremendously to the chemical compatibility and overall life of the mag-drive pump to make it virtually maintenance free.

Impellers and pump bodies are designed to produce efficient flow and head characteristics required in today’s applications. The hydraulic designs, coupled with motors specifically designed for the pump end, means less power consumption for the work performed.

Product Advantage

Leakage free

Magnetic drive seal-less pumps are free from leakage problem and the need for sea replacement. This feature and their compact nature make them ideal for built-in applications.

Large selection

More than 50 models to satisfy a large application selection. The high-head type(model with Z), the high flow type(model with X) and threaded connection type are available as well as a standard hose connection type.

High corrosion-resistance

GFRPP(grass fiber reinforce polypropylene) wet end of the pump handle a wide range of chemical.

Easy maintenance

The pump unit is comprised of small number of integrated parts, so maintenance is greatly simplified.

Working Principle

A seal-less magnet drive pump uses magnet torque to transmit energy from the motor to the impeller. A magnet coupling is formed using an inner, or driven magnet, attached to the impeller and an outer, or drive magnet, attached to the motor shaft.

This design eliminates mechanical shaft seals or packing, since there is no direct connection between the motor shaft and the impeller. The front and rear casings, sealed with a static O-ring, form the pump or liquid end.

The magnetic field is transmitted from the drive magnet through the rear casing to the driven magnet that is attached to the impeller. The combined coupling torque of the drive magnet and impeller magnet provides the driving power to the fluid being pumped.

If you are interested in MP-R magnetic drive pump , just contact us SIKOPUMP freely.

The separate MP-R pump catalog and detailed specification can be provided.

Application for MP-R magnetic drive centrifugal pump

- Chemical industry:

Sodium carbonate industry (production of hydrochloric acid, hypochlorous acid, secondary chemical product); production of fluoride, chemical fertilizer; cycle of reactive liquid of gas absorb tower, abstract grease (sulfuric acid); recycle & reactivation system of waste acid substance; transport of strong acid between chemical factory and transport vehicle. - Pharmaceuticals Industry:

Production of luminophore (EL) for semiconductor, pesticides, medicine, water treatment agent. - Electric plate:

Cycle filter kinds of electroplating liquid. - Photograph processing:

At-once photograph system; X film, wash-out of black and white, color and solid Photograph. - Electrical appliance:

Production of chemical capacitor (erosion by alum inurn film) Transport electrolyte for manufacture of dry battery and accumulator; Etching circuit board: Transfer high purity of chemical high purity of chemical liquid during the manufacture of semiconductor. - Metal industry:

Treatment device for aluminum oxide film; wire stretching; oil elimination and acid cleaning for steel rolling, oil elimination and acid cleaning before painting of vehicle, production of oxidized titanium and rare-earth element.